Serch the Knowledge Base

03. What are The Functions of The Main Components of The Air Flow System in A Screw Air Compressor Unit?

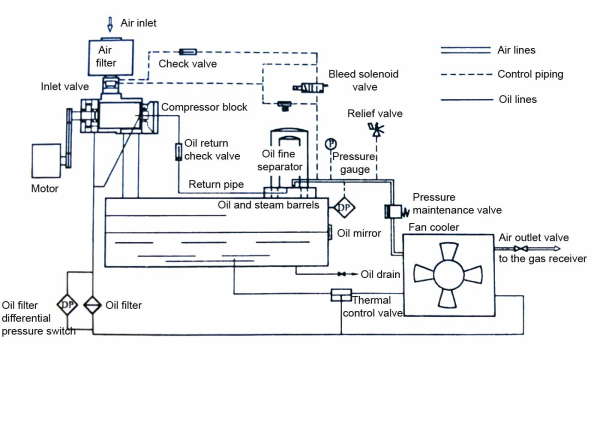

- Air Filter: Filters the incoming air to remove impurities and contaminants, ensuring clean air.

- Inlet Valve: The inlet valve controls the opening and closing of air intake, enabling the loading, unloading, and pressure adjustment of the air compressor.

- Pressure Switch: The pressure switch controls the opening and closing of the intake valve by detecting changes in air compressor pressure, further controlling the electric motor. It can be set to a maximum pressure value, where the intake valve closes and sends a shutdown delay signal to the electric motor. It can also be set to a minimum pressure value, where the intake valve opens or restarts the electric motor.

- Outlet Check Valve: The outlet check valve prevents compressed air from flowing back to the air compressor when the compressor is not running.

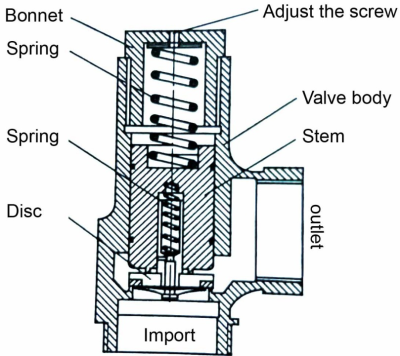

- Safety Valve: The safety valve opens when the pressure inside the oil and gas separator exceeds the rated pressure by 0.1 MPa due to improper adjustment or failure of the pressure switch. It ensures the safety of the air compressor unit.

- Minimum Pressure Valve: Located at the outlet of the oil-gas separator above the air receiver tank, the pressure maintaining valve opens at a pressure set around 0.45 MPa. Its functions include:

-

The structure diagram of minimum pressure valve

Establishing lubricating oil circulation pressure at startup to ensure proper lubrication of the machine.

- Reducing the air flow through the oil-gas separator when the pressure exceeds 0.45 MPa to protect the separator core from damage.

-

- After Cooler: The after cooler cools down the compressed air at the outlet to ensure safe usage and meet the performance requirements of post-processing equipment. It can be either air-cooled or water-cooled.

- Blowdown Solenoid Valve: When the air compressor stops or is unloaded, the blowdown valve opens to release the pressure inside the oil-gas separator, ensuring that the compressor can start under no-load conditions or run without a load. Common blowdown valves include normally open solenoid valves or piston-type blowdown valves.

- Air Tank: The air tank is used to store the compressed air and gas discharged from the compressor. It helps to eliminate pulsations in the exhaust pipeline and serves as a buffer when the demand exceeds the compressor’s capacity. The larger the volume of the air tank, the longer the compressor’s running intervals.

- Water Separator: The water separator collects and removes condensate water separated from the air or gas during the cooling process.

- Automatic Drain Valve: The automatic drain valve automatically discharges accumulated water inside the air tank without manual operation.

Detailed Diagram of Screw Air Compressor System