- What is an oil-free scroll air compressor?

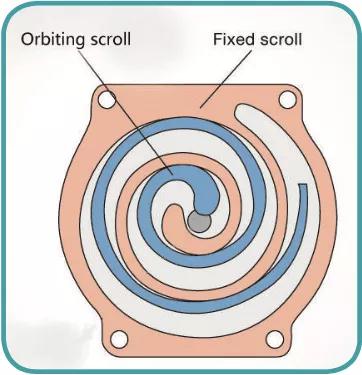

- How does an oil-free scroll air compressor work?

- Advantages of an oil-free scroll air compressor

- What is the service life of an oil-free scroll air compressor?

- How often does an oil-free scroll air compressor need to be maintained?

- Can we reduce the maintenance cost if using an oil-free scroll air compressor?

- Applications of Oil-free Scroll Air Compressor

Oil-free scroll air compressor can be widely used in departments that require high purification gas sources such as grain, oil and food, medicine and health, and scientific research institutes, and is more suitable for general power air source use.

What is an oil-free scroll air compressor?

The oil-free scroll air compressor is a type of dry rotary displacement compressor. The moving parts of the air compressor are all made of self-lubricating materials, and can operate without the need for any lubricating oil. Since the air of oil-free scroll air compressors does not come into contact with lubricating oil, it has high purity and will not pollute the working environment and gas equipment.

How does an oil-free scroll air compressor work?

Elang oil-free scroll air compressor unit comes in three power ratings: 2.2 kW, 3.7 kW, and 5.5 kW, and the entire unit is controlled as an integrated system with multiple units.

Power: 2.2 – 5.5 kw

Working Pressure: 6 – 8 bar

Air Delivery: 0.24 – 0.6 m3/min

Advantages of an oil-free scroll air compressor

Compared to other types of air compressors, some of which may contain oil, generate high noise levels, and have poor stability, oil-free scroll air compressors have distinct advantages. They are oil-free, compact in structure, and produce minimal noise. Additionally, oil-free scroll compressors feature a simple design with only one moving part, making them more reliable and quieter in operation compared to piston compressors and screw compressors. As a result, these types of compressors are primarily used in industries where space is limited, oil-free operation is essential, and noise requirements are high. For example, laboratories find them to be the best choice.

What is the service life of an oil-free scroll air compressor?

The expected service life of an oil-free scroll air compressor is typically influenced by the following factors:

a. Equipment Quality: High-quality oil-free scroll air compressors tend to have longer service life. Choosing a reputable brand and supplier ensures that the equipment’s quality and performance meet your requirements.

b. Equipment Load: Using the oil-free scroll air compressor within its normal operating load range can effectively prolong its service life. Overloading or prolonged operation under heavy loads can accelerate wear and damage to the equipment.

c. Maintenance and Care: Regular maintenance and care of the equipment are crucial for extending its service life. Keeping the equipment clean, well-lubricated, and timely replacement of wear parts can reduce equipment failures and improve its longevity.

d. Working Environment: Suitable working conditions can have a positive impact on equipment service life. This includes factors such as appropriate temperature, humidity, and good ventilation.

In general, the service life of high-quality oil-free scroll air compressors can reach 10-15 years or more. However, the actual service life can be influenced by the specific usage and maintenance of the device.

How often does an oil-free scroll air compressor need to be maintained?

The appropriate maintenance cycle can ensure the normal operation of the equipment and reduce the risk of failures. It depends on the following factors:

Manufacturer’s suggestion: Oil free scroll air compressor suppliers usually provide maintenance manuals or recommendations, including equipment repair cycles and maintenance requirements. Users should strictly follow the manufacturer’s suggestions for repair and maintenance work.

Workload: Users can adjust the maintenance cycle accordingly based on the equipment’s workload. Equipment in heavy working environments may require more frequent repairs and maintenance.

Equipment condition: Users should regularly inspect and monitor the equipment’s operational status to determine if the maintenance cycle needs adjustment.

Regular maintenance of the oil-free scroll air compressor includes cleaning the equipment, replacing wear parts, and lubricating parts among other tasks. Additionally, users should also pay attention to the operation of the equipment at any time, promptly detect abnormal conditions of the equipment, and take corresponding measures for repair and maintenance, which can reduce the risk of failure and improve the reliability and the equipment service life.

Can we reduce the maintenance cost if using an oil-free scroll air compressor?

As an advanced oil-free lubrication compression equipment, the oil-free scroll air compressor has the advantage of lower maintenance costs compared to traditional oil-lubricated compressors.

1. No need to change lubricating oil

Compared to oil lubricated compressors, the most significant advantage of oil-free scroll compressors in maintenance is that they don’t require changing lubricating oil. Traditional compressors require regular replacement of lubricating oil to ensure the normal operation of the equipment, while oil-free scroll air compressors achieve oil-free lubrication through an independent lubrication system without the need for additional lubricating oil. This reduces the cost of purchasing and changing lubricating oil, as well as decreasing the complexity and cost of maintenance work.

2. Reduce maintenance frequency and cost

Oil free scroll air compressors, as they do not require lubricating oil, have lower maintenance frequency and cost compared to oil lubricated compressors. Traditional compressors require regular oil changes and monitoring of lubricating oil, along with maintenance of spare parts such as oil filters and oil separators. In contrast, oil-free scroll air compressors reduce these maintenance steps, requiring only simple maintenance tasks like regular cleaning and inspection of filters. This reduces maintenance frequency and costs, as well as the labor and material inputs.

3. Prolonged Maintenance Cycle

The oil-free scroll air compressor has a long maintenance cycle due to its advanced oil-free lubrication technology and high-quality spare parts. The design and manufacturing of oil-free scroll air compressors have been carefully considered, using high-quality materials and durable components to improve the reliability and service life of the equipment. This reduces the frequency and cost of maintenance, minimizing downtime and its impact on production.

4. Improve equipment stability and reliability

The characteristic of oil-free scroll air compressors is oil-free lubrication, which does not require consideration of oil selection, replacement, and storage, reducing the burden and operational risks on operators. At the same time, the oil-free scroll air compressor will not experience faults caused by aging or pollution of lubricating oil during operation, improving the stability and reliability of the equipment.

5. Regular maintenance to prevent faults

Although the maintenance cost of oil-free scroll air compressors is relatively low, regular maintenance and upkeep are still the key to ensuring long-term stable operation of the equipment. Timely replacement of filter elements, cleaning of air coolers, and inspection of electrical systems and fasteners can effectively prevent malfunctions and reduce maintenance costs and downtime.

Applications of Oil-free Scroll Air Compressor

Dental Application

Friends who have been to a dental hospital for tooth extraction know that doctors use pneumatic tools to polish and perform other operations on the teeth. If these pneumatic tools emit lubricating oil smells and are accompanied by noise, it will definitely be a very bad experience. In such scenarios, oil-free scroll air compressors are well-suited. In such scenarios, oil-free scroll air compressors are well-suited.

Other Applications

Pharmaceutical and Biotechnology

Compressed air is often in direct contact with products or packaging in these industries. Class 0 oil-free air ensures that products will not be polluted. Additionally, given the sterile air requirements during product manufacturing processes, the need for Class 0 oil-free compressed air becomes even more crucial. It can effectively prevent safety issues with products.

Food and Beverage Industry

Oil-free air compressors provide high-quality compressed air for food and beverage manufacturers, serving as the air power and packaging protection gas source. In the food and beverage industry, compressed air comes into direct contact with products during packaging, filling, and sealing processes. Class 0 oil-free compressed air ensures product cleanliness, reduces the risk of product contamination, and effectively prevents potential health hazards.

Chemical industry

The quality of compressed air means safety for the chemical industry. Oil free and high-quality compressed air can effectively help chemical manufacturers reduce risks and reduce the hazards of unknown chemical reactions.

High quality spraying industry

Impure gases often result in poor coating quality, and oil-free compressed air is the foundation of high-quality paint surfaces. It can effectively eliminate oil stains that may hinder paint adhesion and cause premature corrosion, ensure paint adhesion, and avoid foaming.

Textile industry

Jet looms require dry and oil-free air. During the production process, fine nozzles blow air onto the strands to form eddies, giving the yarn shape, elasticity, and elasticity. Oil free compressors can provide pure and high-quality compressed air, ensuring the quality of the finished fabric.

Power industry

Compressed air is primarily used for control instruments, and power generation units require a large number of control instruments to ensure operation. These control instruments are all operated by oil-free compressed air. Additionally, oil-free compressed air is also required for flue gas desulfurization.